When CBN and Diamond super abrasives were introduced approximately 45 years ago, delapena group made the executive decision to purchase honing sticks from leading manufacturers, rather than producing our own. However, as the industry began to see new, exotic materials and difficult to hone components, delapena’s super abrasive offering was not suitable for the marketplace; and so, delapena sintering was born in 2017.

delapena develops and manufactures super abrasives at our state-of-the-art UK production centre. With the capacity to manufacture over 250,000 honing sticks per year, we produce consistently high-quality results. Please get in touch with the delapena team today to discuss your sintering requirements.

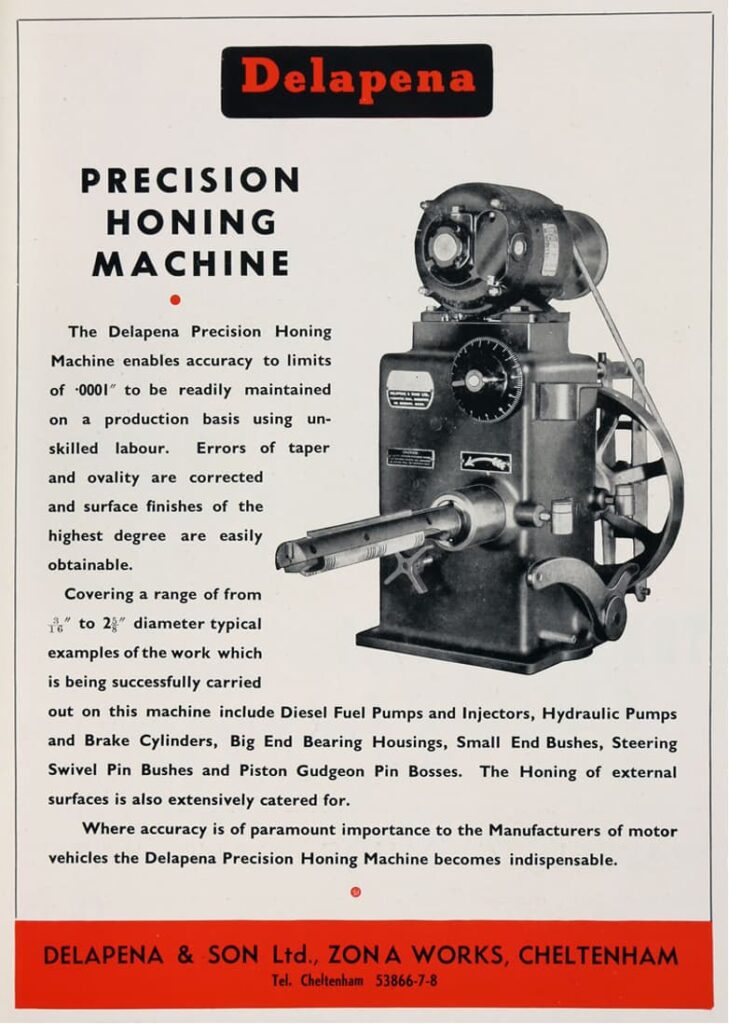

The company was founded in 1927 by Leslie Delapena. Delapena had many contacts in America, and he brought the world of honing to the UK and Europe.

Prior to delapena’s establishment, machinists were boring at very low tolerances; the honing process took surface finishing to a whole new level. During the second world war, Delapena struggled to obtain the product supplies he required, and consequently set up his own manufacturing facility. He developed innovative honing machines that began to be utilised by OEMs and car companies throughout Europe.

delapena was the biggest honing company in the world during the late 1960s and early 1970s. The 1970s was a difficult decade for the UK honing industry, due to excessive inflation – but delapena was still able to thrive during this time.

New CNC machines were introduced in the early 1980s, which decreased the need for honing. However, tolerances have now become much tighter and honing is more accurate than current CNC machines. With the introduction of new honing technology, delapena can now hone down to tolerances of one micron.

Over the last 10 years, delapena has designed an innovative range of honing machines – and will continue to do so. The next 10 years will see the introduction of Industry 4.0, with productivity being the key output. delapena will begin to design new automatic loading machines, incorporating smart technology which can “think for itself”.

delapena group has an impressive history that spans over almost 100 years and we are exceptionally proud of our heritage. We specialise in surface finishing in the bore or on the shaft and boast an impressive portfolio of electronically controlled grinding and honing machines, plus tooling, fixtures, abrasives and oils to support honing operations across the globe. We have a worldwide reach, with machines supplied across all continents.

delapena group is a master in the honing and grinding market, offering solutions for every honing need. delapena is synonymous with quality and is regularly used as a verb in the engineering world as the definitive for honing. We readily share our knowledge and expertise, making us a trusted and valued partner. Our focus is on delivering the precision and consistency that our customers rely upon, whilst ensuring we support a process that is easy, rapid and responsive.

delapena group has representatives in 50 different countries. All our agents and distributors have grinding or honing experience, as well as technical competence. Boasting an online shop as well as welcoming bespoke commissions, and offering comprehensive in-house technical support, we will endeavour to fulfil all your honing wants and needs.

© 2025 delapena group Ltd.